ABOUT US

One of the fastest-growing plastic injection molding companies in Indonesia.

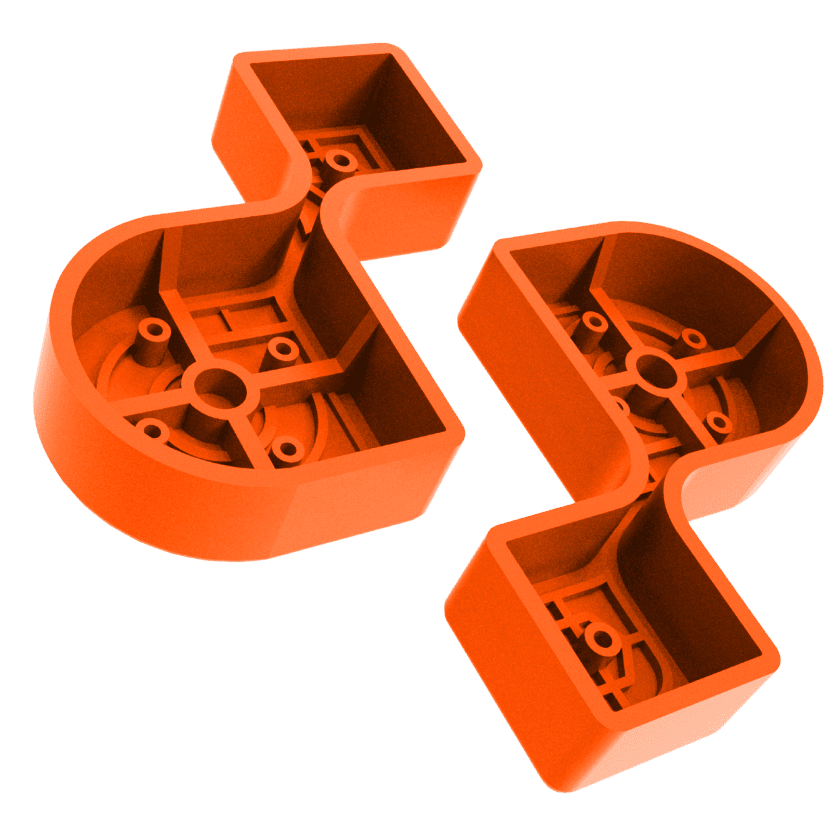

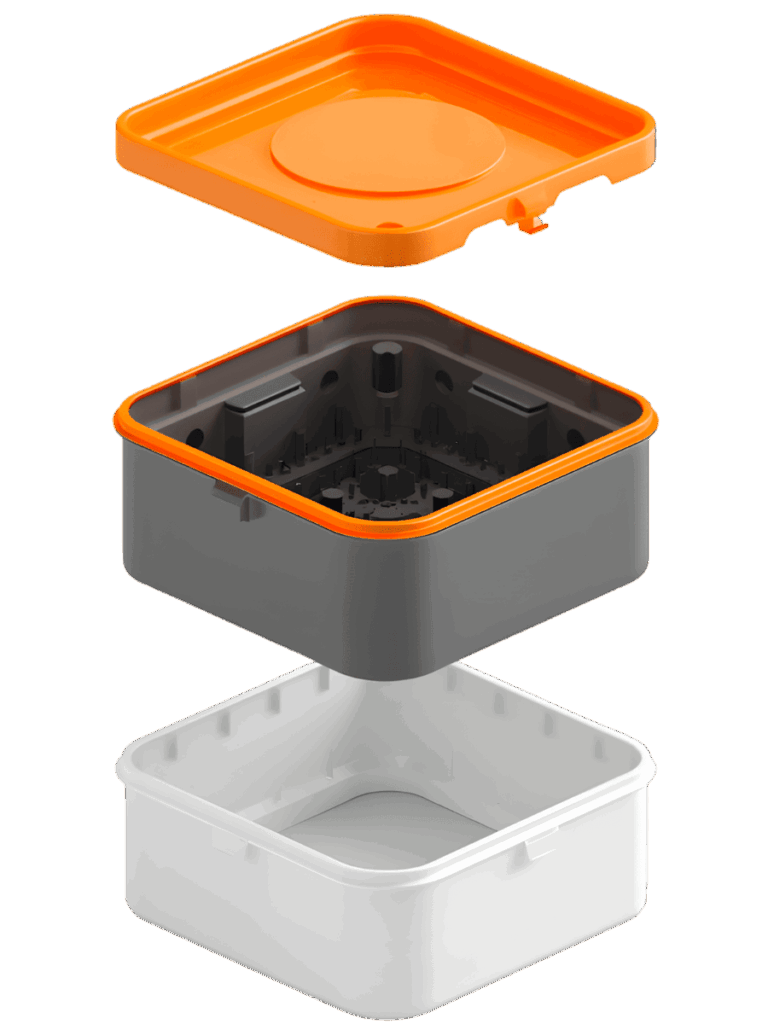

PT Dinamika Polimerindo operates machines ranging from 40 to 650 tons to support industries from automotive to FMCG. Our clients trust us for reliable partnerships, consistent quality, and seamless delivery. From design to mass production, we provide end-to-end injection molding services backed by ISO 9001, IATF 16949, and TKDN compliance.

OUR CAPABILITIES

Your trusted partner for injection molding in Indonesia, from concept to production. Delivers reliable, precise, and globally compliant parts.

CERTIFICATIONS

WHY US

A Reliable Partner for Injection Molding in Indonesia. Delivering innovation in plastic injection molding and mold manufacturing since 1996.

01

Reliability with On-Time Delivery

Our customers trust us for unmatched reliability and dependable on-time delivery, ensuring every project runs smoothly from prototype to production.

02

30+ Years of Industry Experience

Since 1990, we have served automotive, FMCG, electronics, and other industries—bringing decades of know-how to every project.

03

Modern Facilities & Integrated Capabilities

With 40–650 ton molding machines and in-house mold manufacturing and assembly, we provide a fully integrated production system that supports both low-volume and large-scale runs.

04

Local Regulation Expertise (TKDN Support)

We understand Indonesian TKDN compliance and international quality standards—helping clients achieve seamless market entry with confidence.

Driven by Experience, Powered by Innovation

Years of Experience

Serving global and Indonesian industries since 1996.

Parts Produced Annually

Trusted supplier of consistent, high-quality plastic components.

Tons of Recycled Material Reused Each Year

We help our customers reduce landfill waste and achieve their sustainability goals.

A Young, Dynamic and Agile Team with a Growth Mindset

Combining decades of expertise with innovation for tomorrow.

OUR CLIENTS

Frequently Asked Questions.

What plastic materials can you process?

We commonly mold PP, ABS, Nylon (PA6/PA66), PC, and HDPE. We also work with custom blends and recycled resins depending on project requirements. If you have a specific resin grade in mind, our team can advise on compatibility and mold performance.

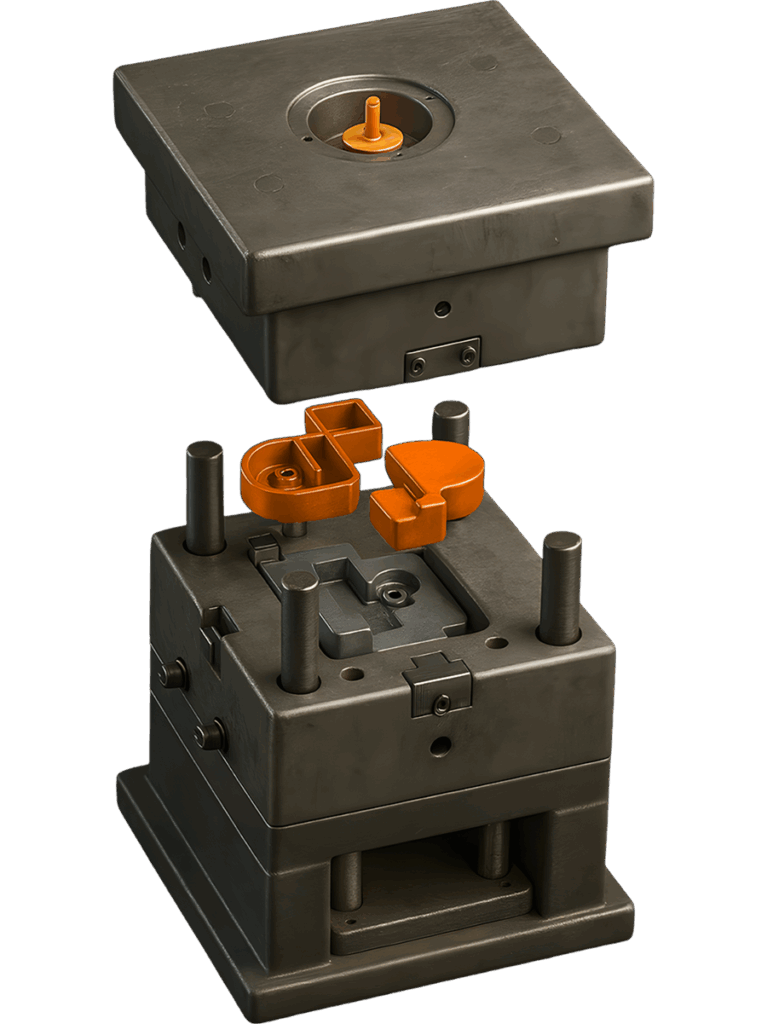

Do you provide mold design and manufacturing services?

Yes. We offer in-house mold design and manufacturing using CAD/CAM systems. Every mold goes through a Design for Manufacturability (DFM) review to ensure proper flow, cooling, and ejection before production. This reduces risk, lowers cycle times, and extends mold life.

Are your products TKDN-compliant in Indonesia?

Yes. We have extensive experience with TKDN certification and Indonesian compliance standards. Our team can provide documentation and guidance to help you meet both local TKDN requirements and international regulations smoothly.

Can you handle high-volume production orders?

Yes. With injection machines ranging from 40 to 650 tons and multi-shift scheduling, we regularly handle large-scale production runs. Our facility is structured to scale from prototype volumes to millions of parts annually, with stable quality across every batch.

What is your typical lead time for production?

Lead times depend on the project scope. Prototype and low-volume runs can be delivered within a few weeks, while new mold builds and mass production typically require 8–12 weeks. We always provide a detailed schedule during the quotation stage.

Do you have a minimum order quantity (MOQ)?

We are flexible with order sizes. For prototype and validation parts, we accept low-volume injection molding. For mass production, MOQs vary depending on part size, material, and tooling requirements.

Can you export parts internationally?

Yes. We supply both local Indonesian clients and international customers. Located just 5 km from Soekarno-Hatta International Airport, our facility is well-positioned for fast export logistics.

Do you use recycled materials?

Yes. We reuse more than 650 tons of recycled plastic annually. This helps customers reduce cost and environmental footprint, while still maintaining consistent quality standards.

How do you ensure quality consistency?

Every project follows strict ISO 9001:2018 and IATF 16949:2016 standards. We use in-process inspections, SPC monitoring, preventive mold maintenance, and full traceability to ensure every batch meets customer specifications.

Still have questions?

Let’s discuss your requirements for plastic injection molding in Indonesia.