Injection Molding Indonesia

With 40–650 ton injection molding machines and a skilled engineering team, we produce parts with tight tolerances and repeatable accuracy. Our facility serves automotive, FMCG, electronics, and medical industries, supporting everything from prototypes to millions of parts annually.

Key Benefits:

- Consistent accuracy and repeatability.

- Cost efficiency at low and high volumes.

- Fast turnaround from prototype to mass production.

Mold Manufacturing & Maintenance

We design, build, and maintain high-quality molds in-house using premium tool steel, CAD/CAM design, CNC, and EDM machining. Preventive maintenance programs extend mold life, reduce downtime, and keep production running smoothly.

Key Benefits:

- Long-lasting molds with consistent performance.

- Lower downtime and maintenance costs.

- Reliable product quality across every cycle.

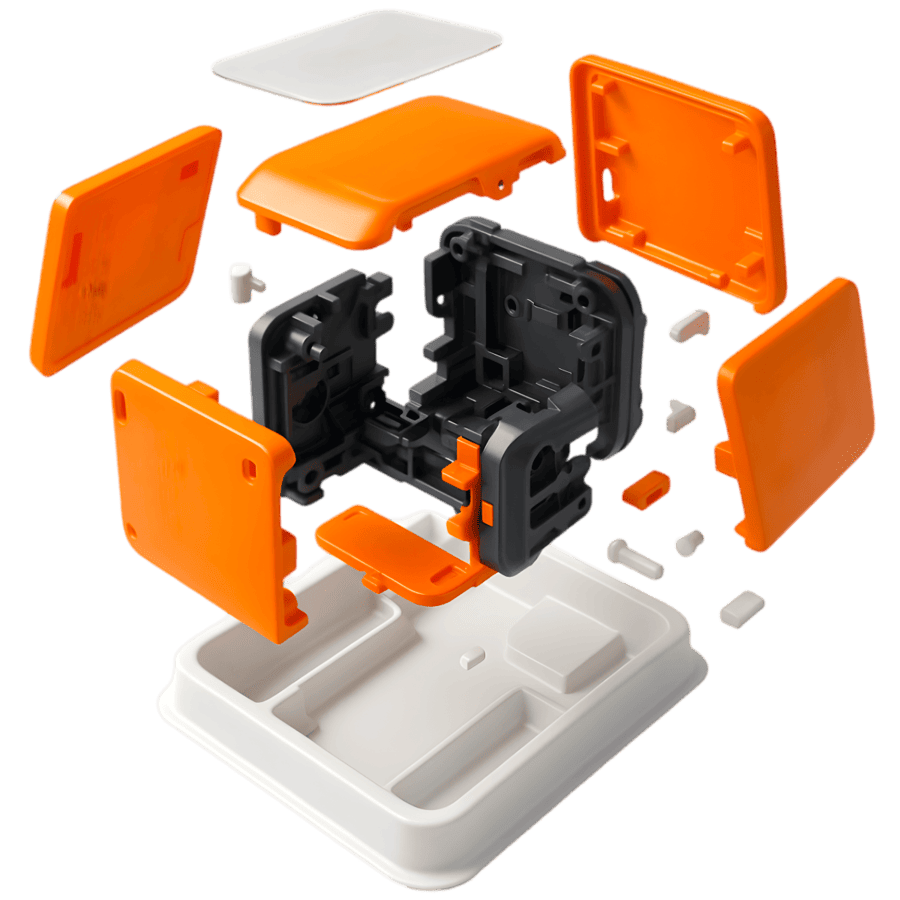

Part Assembly & Secondary Processes

We go beyond molding with assembly and value-added processes such as sub-assembly, integration with accessories, packaging, and finishing. By keeping assembly in-house, we simplify the supply chain and reduce lead times.

Key Benefits:

- One-stop solution from molding to finished product.

- Lower logistics and outsourcing costs.

- Faster delivery of market-ready components.

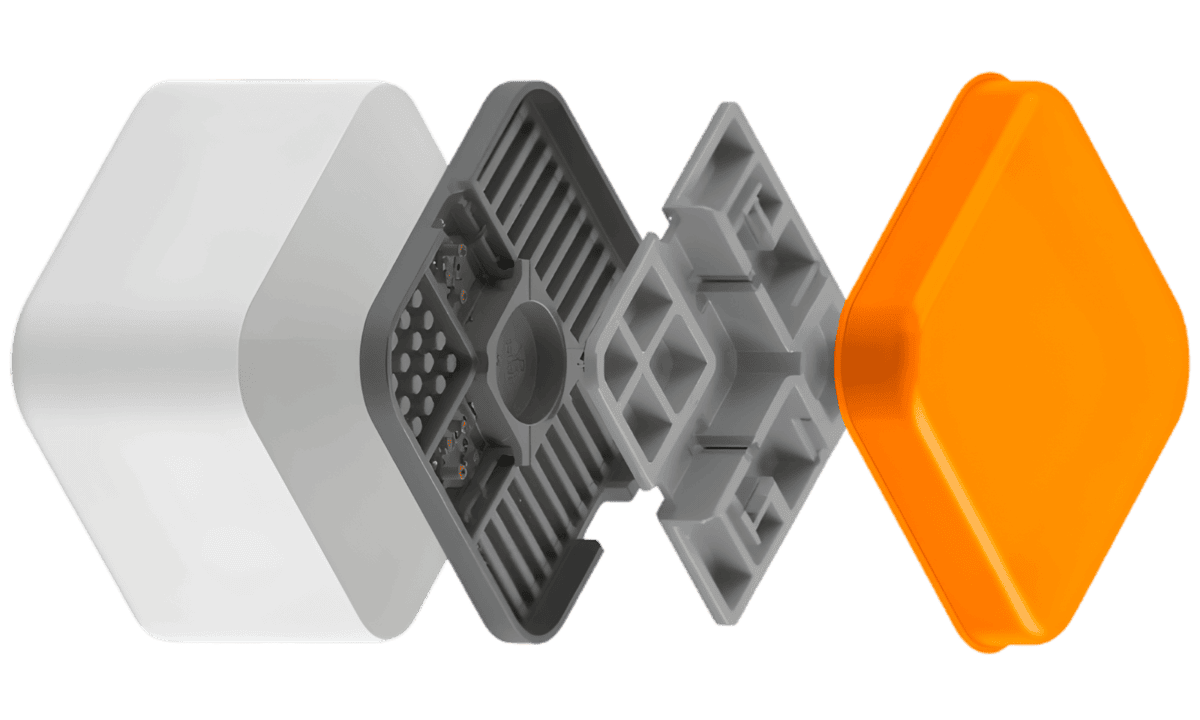

3D Design, Prototyping & Low-Volume Injection Molding

Our 3D design and prototyping services in Indonesia accelerate product development. Beyond 3D printing, we offer prototype molds and low-volume injection molding, enabling testing with actual production materials (PP, ABS, Nylon, PC, etc.) before scaling up. This ensures better functionality, lower risk, and reduced cost at launch.

Key Benefits:

- Faster design validation and product iteration.

- Functional testing with real materials.

- Lower risk and cost before mass production.